OVERVIEW

Breweries and Distilleries require specialised flooring systems designed to withstand the everyday impacts of their harsh production environment. Multiblast’s epoxy, polyurethane and various other resin flooring systems are the ideal solution for breweries, designed to withstand chemical exposure and high impact over a long period of time. Our specialised floors continue to provide an attractive, safe, and easy to clean surface in accordance with the Australia New Zealand Food Standards Code.

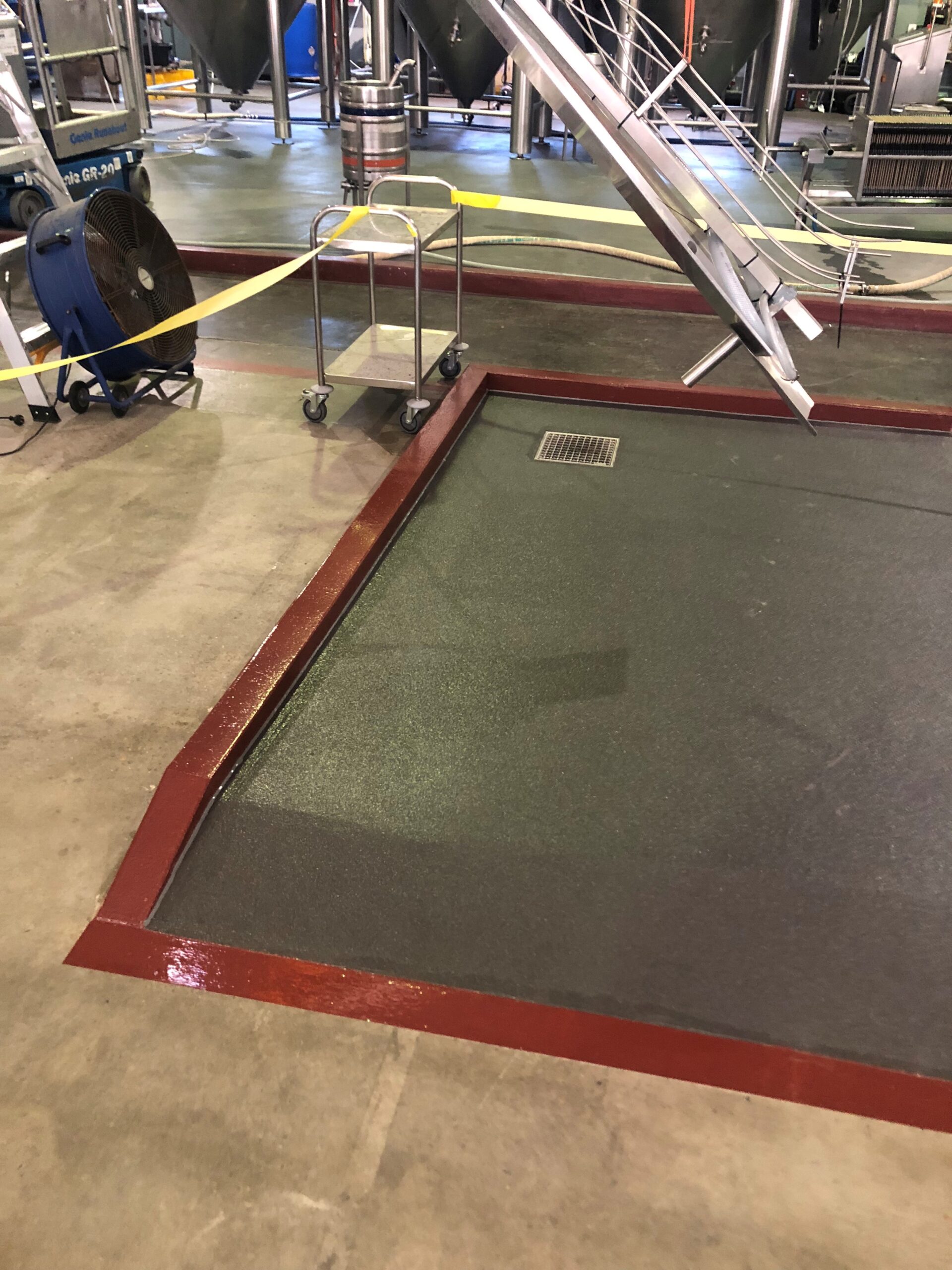

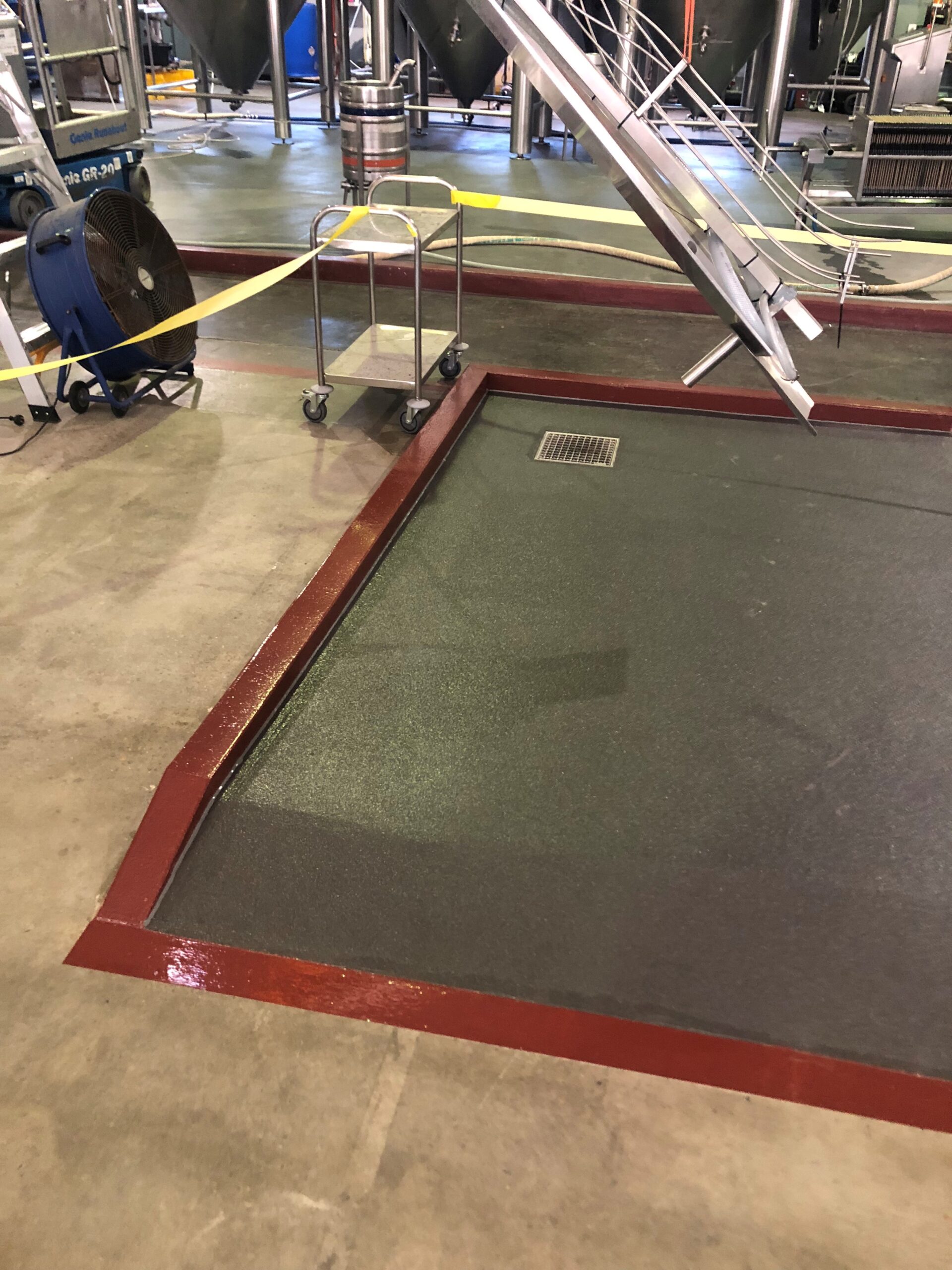

At Multiblast, our industrial flooring systems can be tailored to suit the business needs of any commercial production design. With the ability to install customised coving, bunding & falls to wastes, whilst maintaining a seamless, impervious antimicrobial coating.

Durable & Impact Resistant

Slip Resistant & Safe

Chemical Resistant

Easy to Clean

Antimicrobial + HACCP Certified

Custom Design

Longevity

APPLICATION SUITABILITY

-

Brewhouse / Tank / Tap Rooms

-

Canning Plants/ Bottling / Kegging Rooms

-

Production / Storage / Laboratory

-

Wet / Bunded Areas

-

Retail / Bar / Amenities / Kitchen

-

Loading Docks

-

Freezers & Cool Rooms

Brewhouse / Tank / Tap Rooms

Canning Plants/ Bottling / Kegging Rooms

Production / Storage / Laboratory

Wet / Bunded Areas

Retail / Bar / Amenities / Kitchen

Loading Docks

Freezers & Cool Rooms

FEATURES

Durable & Impact Resistant

The production floor in a brewery is continuously exposed to harsh chemicals, heavy impact & loads from equipment, moisture, thermal shock, and rigorous cleaning standards. To protect against contamination & safety hazards, it is vital that an appropriate, hard-wearing flooring system is installed.

Slip Resistance and Safety

With the ability to deliver a non-slip finish and customised demarcation & line marking, our floor coatings help to protect the safety of staff whilst also maintaining Workplace, Health & Safety requirements. With the inclusion of Silica Quartz and Aluminium Oxide grit additives during the coating process, we can alter the texture & slip resistant properties of the finished floor. Traction can be improved, and a slip rating (P0 to P5) can be achieved with NATA approved slip test reporting available in accordance with the Australian Standards.

Chemical Resistance

Due to its impervious & inert non-reactive properties, our Brewery coating systems are specifically designed to be resistant to many products & ingredients used in the Brewing process. This includes yeast, alcohol, malts, enzymes, brewing sugars, organic acids, alkalis, and cleaning agents.

Easy to Clean

The seamless, impervious nature of our flooring systems, combined with customised coving, bunding & drainage options, allows for staff to quickly and easily sterilise & wash away grime and dirt that accumulates during a busy working day. This helps maintain a clean, organised, and safe workplace that complies with the sanitation regulations of the Australia New Zealand Food Standards Code.

Antimicrobial + HACCP Certified

Specifically designed floor coating systems with a silver-ion based antibacterial additive that is certified to eliminate up to 99.9% of bacteria (ISO 22196 + HACCP Certified). Natural silver is renowned for its ability to protect against bacteria, making it an environmentally friendly alternative to chemically manufactured antimicrobials.

Custom Design

A seamless floor finish available in a range of colours to suit any unique aesthetic and decor. Tailored line marking, safety walkways and signage incorporated into the floor finish, not only improves appearance, but helps to ensure staff and visitor safety.

Longevity

A quality long-term flooring solution specifically designed to suit the needs of your Brewery to minimise costly maintenance shutdowns.

GALLERY

SYSTEM DESIGN EXAMPLE

1. Polyurethane Cement Sealer

2. Full Grit Broadcast

3. 4-6mm Polyurethane Cement

4. Primer Coat (optional if required)

5. Prepared Concrete Substrate

ReQUEST A QUOTE OR CALL OUT

Car Park Coating SYSTEMS

RECENT PROJECTS

WHO WE HELP

OUR CLIENTS